In today’s volatile global supply chain landscape, direct material procurement is no longer just a back-office function - it is a strategic leverthat drives resilience, agility, and profitability. As manufacturers face pressure to reduce costs, mitigate risks, and accelerate time-to-market, traditional procurement models are proving inadequate.

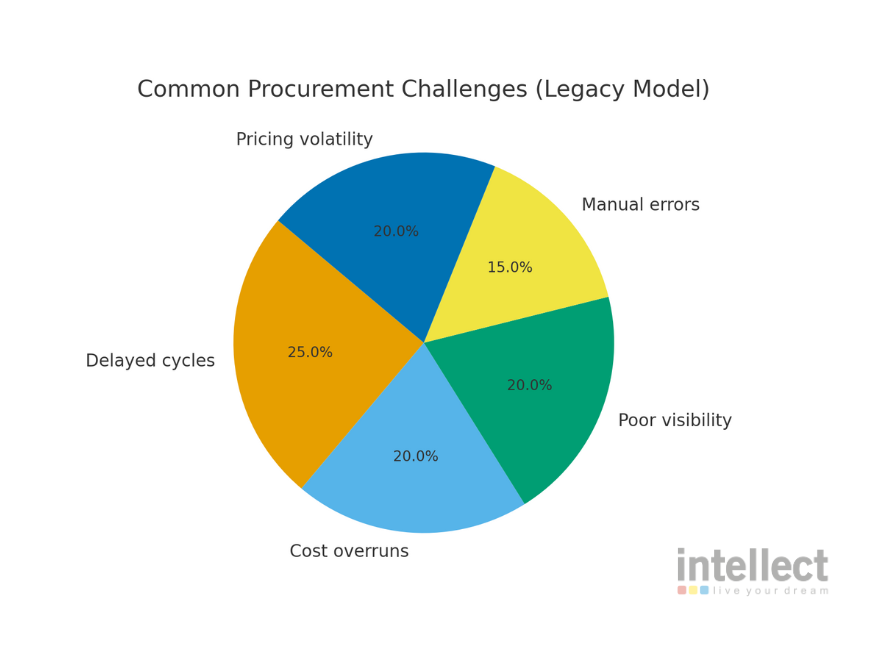

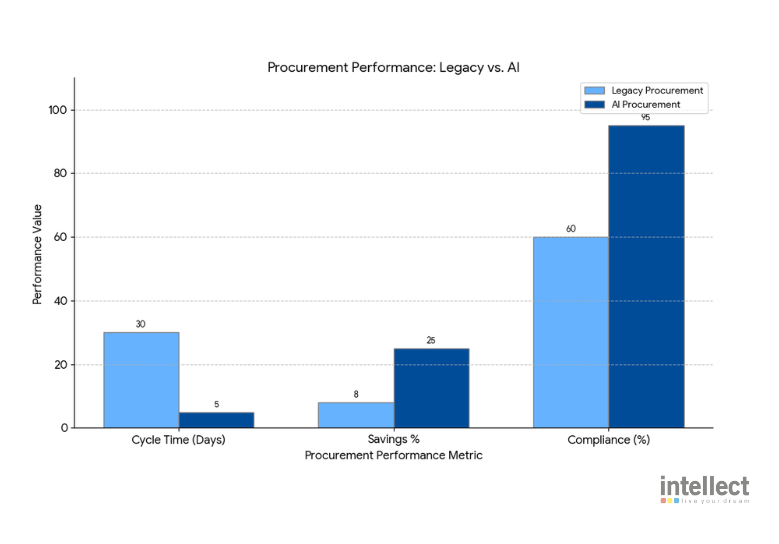

At the heart of this transformation is AI-driven Source-to-Pay (S2P) technology, which offers a unified, intelligent approach to sourcing direct materials. The numbers show why it’s no longer optional but essential.

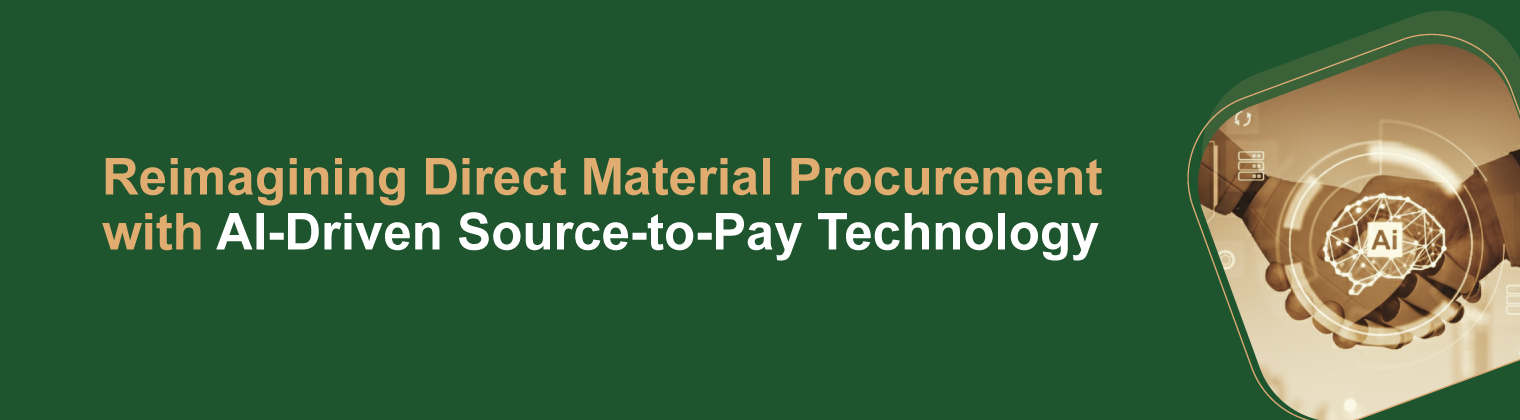

The Legacy Procurement Challenge

Traditional procurement processes rely on fragmented systems, manual inputs, and siloed data. This leads to measurable inefficiencies:

- Delayed cycles: Tender evaluations can take weeks; AI has been shown to reduce RFx evaluation time by 66% (McKinsey).

- Cost inefficiencies: Manual negotiation leaves money on the table; AI-powered supplier negotiation has delivered 40% cost savings in real-world deployments (Emoldino case study).

- Lack of visibility: Over 50% of organisations cite poor visibility into supplier data as a major procurement pain point (Falcon Fulfillment).

- Error-prone manual work: A mining company reported 200,000+ supplier emails per year, with high errors and delays due to manual handling (Quoreka).

- Volatile pricing: Without analytics, procurement teams cannot validate raw material price hikes (aPriori).

AI-Driven S2P: The Unified Solution

Modern AI-powered S2P platforms, like iCPX, integrate sourcing, procurement, invoicing, and supplier management into a single intelligent ecosystem.

Key Capabilities:

- Smart Supplier Discovery: AI evaluates potential partners based on a comprehensive set of criteria, including performance history, delivery reliability, compliance records, and competitive pricing, ensuring you partner with the best fit.

- Automated RFx Management: Streamlines the entire ‘Request for X’ process with features like pre-filled RFQs, optimised timelines, and predictive supplier response analysis, dramatically cutting down the sourcing cycle.

- Predictive Spend Analysis: Goes beyond historical reporting to forecast future demand, flag unusual anomalies, and proactively identify cost-saving opportunities by suggesting optimal buying strategies.

- Dynamic Approval Workflows: Uses context and data to initiate intelligent, context-based routing for faster decision-making and ensures compliance is met without unnecessary delays.

- Invoice Reconciliation: With AI-driven 2-way and 3-way matching, invoices are automatically cross-verified against purchase orders and goods receipts, eliminating manual effort, minimising errors, and accelerating reconciliation.

- Supplier Risk Monitoring: Continuously tracks and alerts on potential threats, including financial instability, geopolitical events, and compliance risks in real time, allowing for proactive mitigation.

Real-World AI Procurement Impact

This data highlights how AI is delivering concrete, measurable results across various industries:

- Spend Reduction: A major pharmaceuticals firm achieved 10% spend reduction using AI-driven “should-cost” analytics (McKinsey).

- Operational Savings (Metals & Mining): The sector saw 7.5% procurement savings, a 60% drop in transactional costs, and an 18% reduction in maverick spend (Quoreka).

- Time Efficiency (Generative AI): Generative AI can create up to 80% time savings in high-volume tasks, such as document handling (KPMG).

- Advanced Insights: 78% of organisations now rely on AI for sophisticated spend analytics and advanced insights (APQC).

- Rapid Adoption: Usage of Generative AI in procurement has surged, with a +44 percentage point jump from 2023 to 2024, and 94% of leaders now using it weekly (Art of Procurement)

Challenges and Solutions in AI-S2P Adoption

| Challenge |

Evidence |

Solution |

| Data silos & integration |

Disparate ERP & supplier systems |

Start with ERP integration pilots, harmonise data |

| Change resistance |

Users distrust “black box AI” |

Phased rollout, explainable AI, training programs |

| Compliance risks |

Sensitive supplier data at risk |

Role-based access, encryption, and audit trails |

| ROI uncertainty |

Hard to measure value |

Define KPIs upfront (savings, cycle times, exceptions) |

| Model drift |

Supplier patterns change |

Regular retraining & monitoring of AI models |

The Strategic Edge of AI-Driven Direct Material Procurement

By shifting from a purely tactical approach to a truly strategic one, AI-driven procurement unlocks significant advantages:

- Faster time-to-market: AI integration dramatically reduces procurement cycle times, often cutting them from weeks to just days, accelerating product development and delivery.

- Cost optimisation: Through advanced analytics, AI enables smarter negotiations and more competitive bidding, leading to substantial cost reductions in direct materials.

- Enhanced risk management: AI platforms provide continuous monitoring of supplier health and potential disruptions across the supply chain, allowing for proactive mitigation of risks.

- Achieving sustainability goals: AI can filter and prioritise eco-friendly suppliers and ensure adherence to environmental and social compliance standards, supporting corporate sustainability initiatives.

- Boosted business credibility: With these strategic capabilities, procurement evolves from being perceived merely as a cost center to becoming a key innovation enabler and a strategic partner within the business.

Conclusion

Reimagining direct material procurement with AI-driven S2P technology is not just a digital upgrade, it’s a strategic evolution. By embracing platforms like iCPX, procurement teams gain speed, precision, foresight, and resilience.

In an era where supply chain disruptions are constant, those who adopt AI-driven procurement today will lead towards a smarter, faster, and stronger tomorrow.